Рекуперація теплової енергії – Ваше найкраще рішення!

Тепло, за вироблення якого ми спочатку платимо, потім платимо знову за електроживлення вентиляторів, що охолоджують, і, нарешті, платимо ще раз за вироблення додаткового тепла для гарячої води, систем опалення та прикладних процесів на інших ділянках підприємства.

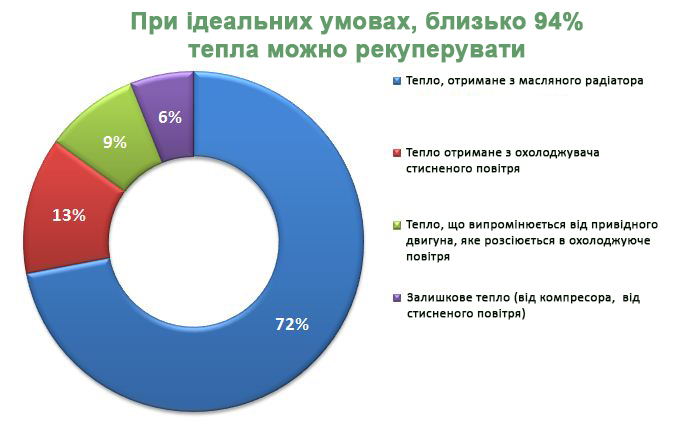

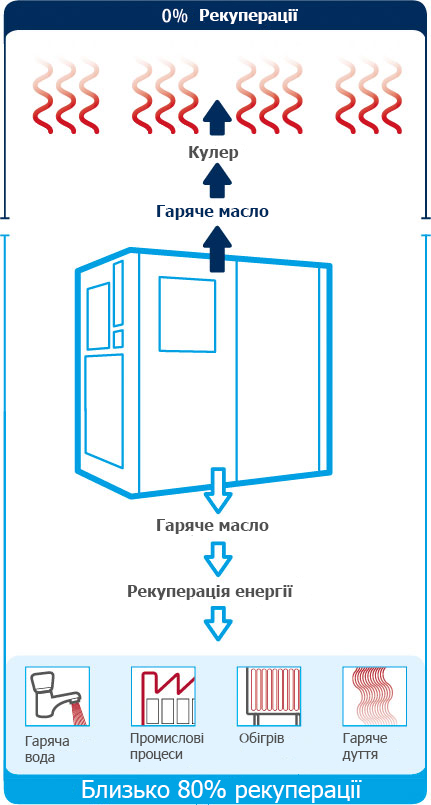

Тепло – це не відходи підприємства, а цінна енергія. Найбільша частина енергії, яка використовується на генерацію стисненого повітря, віддається у вигляді тепла, та вивільнюється за допомогою охолоджуючого середовища (повітря/води). Це охолоджуюче середовище містить близько 94% вхідної електричної енергії. Це тепло не повинно пропасти, а має бути використане, наприклад, в обігріві приміщень чи води. До 80% вже використаної енергії можна рекуперувати.

Ви економите енергію всюди, де використовуєте рекуперацію в якості допоміжного джерела для зниження експлуатаційних витрат. Інвестиції, що необхідні для приєднання гарячої води з компресора до уже наявної схеми можна здійснювати при відносно невеликих витратах та у короткий термін окупності.

Принцип рекуперації тепла полягає в передачі теплового ефекту стиснення в теплоносій, а потім доставці теплоносія туди, де можна використовувати рекупероване тепло. В середині компресора тепло, вироблене стисненням повітря, поглинається охолоджуючим маслом. Масло, яке тепер стало гарячим, циркулює під тиском та проходить через пластинчатий теплообмінник. Потім, тепло подається на вхід водопостачання, підігріваючи воду, і, в той же час, охолоджуючи масло. Гаряча вода потім поставляється в будь-яку установку, де в ній є потреба, наприклад, парогенератори, миючі установки, котли, опалювальні системи та інше.

За кожний градус, на який ми піднімаємо температуру води, необхідно заплатити. Тому, якщо ми маємо подачу води, яка вже на 60° за Цельсієм вища стандартної температури водопостачання, то отримуємо 60° тепла, за які ми вже повторно не платимо. Попередній підігрів води для опалювальної системи та гарячого водопостачання за допомогою промислових процесів, таких як парогенерація, може забезпечити значну економію коштів та окупитись дуже швидко. Додаткове тепло, що не поглинається охолоджуючим маслом, відводиться через систему вентиляції т виходить з неї у вигляді гарячого повітря. Це гаряче повітря зазвичай тратиться в пусту, але встановивши повітропровід для системи рекуперації тепла, гаряче повітря можна направити на різні ділянки підприємства. Ви також можете переключити заслінку в системі вентиляції для виводу повітря назовні влітку, коли воно не затребуване в середині приміщення.

Ми допоможемо Вам використати залишкову теплову енергію, використовуючи систему рекуперації енергії. Це дасть Вам можливість досягнути значної економії енергії, зниження затрат, покращення продуктивності та більше скорочення викидів.

Модуль системи рекуперації забезпечує подачу гарячої води в цех, майстерню чи офіс за допомогою тепла, процесу стиснення повітря в компресорній установці.

В залежності від фактичного навантаження компресора, система рекуперації енергії може нагріти воду до 75°С в контурі циркуляції.

Гаряча вода може бути використана для наступних цілей:

Гаряча вода може бути використана для наступних цілей:

• Загальні: системи обігріву, душові, подача гарячої води

• Господарські: бойлери, пастеризація, сушка та опалювальний процес, стерилізація

• Процеси: синтез газу, паровий крекинг, зачистка, нагрівання бойлеру

• Фармацевтика: підтримка температури, сушка, стерилізація, парові бар’єри

• Текстиль: фарбування, обробка

• Турбіна: зволоження, рібойлер, очищення середовища

А також для використання в процесах гальванізації або фосфортування металів.

Системи рекуперації тепла забезпечують максимальну ефективність шляхом вилучення енергії, що виробляється в процесі виробництва стисненого повітря. Система дозволяє зново використовувати до 90% енергії. Термостатичний контроль підтримує задану температуру в компресорі.

Варто зазначити, що модуль рекуперації теплової енергії може бути встановлений на будь-які моделі компресорів – як на нові, так і на ті, що знаходяться в експлуатації. Модуль може бути встановлений на будь-якому етапі роботи компресорного обладнання.

Встановлення системи рекуперації тепла Gardner Denver може виявитись на диво економічно вигідним, та стати одним з найкращих рішень, яке Ви приймете у цьому році.

Контакти:

Головний офіс:

Україна, Київ,

вул. Петропавлівськая, 54 а

тел.: +38 044 467 26 01

факс: +38 044 467 26 07

kiev@compressors.ua

Сервіс-центр:

тел.: +38 044 467 26 02

факс: +38 044 468 02 96

service@compressors.ua